Introduction

The modern manufacturing industry is filled with huge customization demands. The injection molding technique has been in Use by manufacturers for decades. However, injection molding alone cannot meet the various complex functional requirements of product manufacturers. To compensate for these increased functional demands, side action injection molding has been introduced.

Side action molds not just improve the functionality of the products but also enhance the process efficiency. They create complex undercut geometries both internally and externally, leading to product variations and functionalities.

In this blog, we shall provide a detailed analysis of side action molds, from their definition to their process and advantages. At the end of the blog, we shall know why the process is quite challenging yet still worth it. From types to the purpose of side action molds, everything is worth to be known, especially for a perfume bottle manufacturer.

What is Injection Molding Side Action?

Injection molding side actions are also known as inserts or features. These are an addition to the molds. Basically, injection molding side action is a modern way to overcome the limitations of the old-school injection molding technique.

Injection molding side action creates undercut geometries. If you want to achieve intricate part designs for your product, then you need to use injection molding side action.

By using a standard straight pull mold, it is impossible to produce undercut geometries. Their injection molding side action features are perpendicular to the main parting line. So, when you use the inserts, you enable the material to flow around, leading to the production of undercut features or geometry.

These side actions follow a cam-driven mechanism. This mechanism also helps in safe erection from the mold parts.

Why do we Need Side Actions?

The purpose of injection molding side action is clear from its definition i.e. creation of complex undercut geometries or intricate patterns. Using the straight pull mold, it is impossible to produce intricate patterns; therefore, we need side actions to produce intricate, complex designs.

Since customization is at the heart of the manufacturing industry these days, side actions or inserts provide endless design possibilities.

In the case of perfume bottle manufacturing, injection molding side action provides opportunities to designers to create customized complex designs in perfume bottles and perfume caps.

Working of Side Action

A standard mold consists of two parts. Therefore, it must produce simple undercut designs. Side actions or inserts create undercuts. These undercuts are actually inward-facing angles or projections.

Inward-facing angles make the part removal process very convenient yet challenging. To address this challenge, manufacturers use lateral movements to detach parts from the mold. The lateral movements cause a sideways slide. Not only does this facilitate the creation of undercuts, but it also prevents any damage to the material.

The interlocking of angle pins is also important to the creation of undercuts. For this, the precise positioning of angle pins is important. Therefore, it is advised that the whole process be performed under expert guidance. The purpose of these angle pins is to drive the side actions into their correct positions.

Accurate positioning of side actions during mold closure can lead to safe ejection later. To ensure seamless operations, manufacturers use hydraulic or mechanical actuators. The second most important thing is the retraction of side actions. Controlled and accurate retraction of side actions not only prevents damage to molded parts but also increases the overall efficiency of the process. Keep in mind that we are talking about controlled retraction before part ejection with undercuts. This lets the undercut and intricate designs remain intact.

Types of Side Actions

Side actions have further classifications. In this section, we shall look at the different types of side actions that are available. Understanding different types of side actions is important because it helps in the selection of the appropriate side action for a particular injection molded part. If you select the right type of side action for your injection molded part, you can increase the efficiency of the tools. This lets the tools last longer.

Let’s have a look at the various types of side actions available in the market.

Lifters

Lifters are the best choice when you want to avoid the usage of angled pins. Since angled pins can cause various pin deformations resulting in the creation of faulty undercuts therefore lifters are used to eliminate this possibility.

When you are designing parts with internal undercuts, and you want them to release without a draft, then lifters are the best choice of side actions. Such undercuts include threads and bosses. Threads are common in perfume bottle caps. The point to note is that both threads and bosses also require a specific orientation.

A cam activates the lifters during tool closure. Retraction occurs while the tool is opening.

Injection mold design using a lifter can be both challenging and therefore require proper planning.

Cams

Cams or cam pins are unique because of their compatibility with other side actions, such as sliders and lifters. Cam S are actually clever mechanisms.

Why?

Because they help in the smooth withdrawal of undercut mold surfaces from the part during mold opening, they make sure that the molded part has precise and accurate undercut geometries. Cams are what differentiates the side actions from the traditional injection molding processes.

However, to control the action movements cam use angled pins. These angled pins control the opening and closing movement of the mold.

Cams make sure that the manufactured parts have complex geometrical patterns. They also reduce the need for secondary mechanical operations such as drilling.

Unscrewing

Unscrewing side actions create screw or threaded features in molded parts. For this purpose, machines such as automated screwing machines or manual turning screws are also used.

Precise control of the screwing process is important. It is because it impacts the quality of the thread and damage between screwing and unscrewing cycles. In other words, we can say that the screws are accurately twisted and untwisted during the process.

What makes unscrewing unique from other options is that this mechanism is inserted into the mold before injection. It is removed from the material after completion of the whole process when the material has hardened. Removal of parts with this side action is also complicated.

Sliders

Just as lifters create internal undercut features, sliders create external undercut features. Sliders are the best type of side actions when creating parts that require complex external geometries or patterns.

Sliders create complex external geometries with the help of versatile actuation options. These include:

- Cam- driven

- Solenoid driven

- Hydraulic-driven

Sliders are the best option when you want to create parts that need to be released without impacting the main part or cavity. They do this through the creation of external features such as threads. However, slider usage is also a very complex process. Accurate synchronization and positioning with other mold parts is important.

Collapsible Core

A Collapsible core is quite similar to lifters. It makes the release of circular undercut features quite easy. There is a reason behind the name collapsible core. This is because, during the molding process, the parts are formed around the side action. Once the part solidifies, the side actions collapse. Hence, the name collapsible core.

These side actions collapse inwards. This facilitates the process of part ejection. It is because of this ejection that a collapsible core is an ideal option for large threads and circular undercuts.

They are a more versatile option than other threads. This is because they also have applications in the formation of threaded features.

Manufacturing of Side Action Molds

Now that we know about the definition, purpose, and types of side actions, we can begin to understand the manufacturing of side action molds. Manufacturing side action molds is a complex step-by-step process. Each and every step requires careful attention to make the final product precise and accurate.

Let’s have a look at each step-in detail:

- Design Phase

Similar to most manufacturing processes, the manufacturing of side action molds also begins with the design phase. The design phase requires participation from manufacturers, engineers and designers. During the design phase, several factors are considered. These include:

- The thermal expansion of the material

- Stress Analysis

- Selection of the material itself

CAD or computer-aided design is used for design and simulation purposes.

It is in the design phase that the designers and other stakeholders analyze the mechanical considerations such as mold ejection and cam and slide movements.

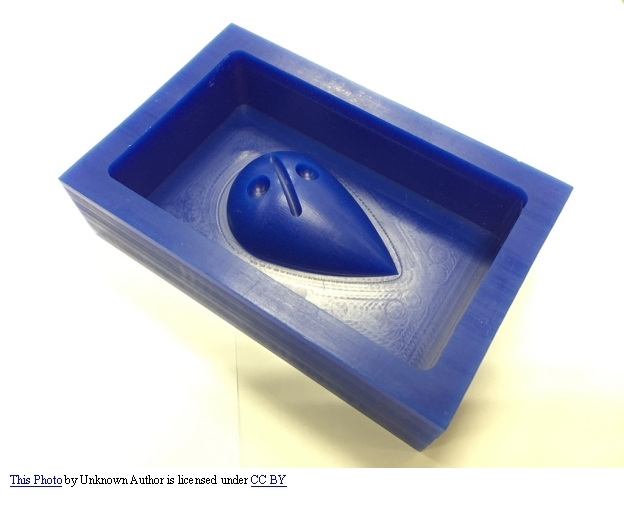

Mold Selection

If you want to achieve optimal performance, then choose mold material and side action components wisely. The injection molding process is a tough procedure. The mold material should be durable and strong enough to bear the challenges of the injection molding process.

Therefore, choose a mold material that has the required strength, durability and thermal properties. Most common materials for mold selection are aluminum, copper and steel alloys. However, all these options have their own strengths and limitations.

You have to consider several factors for the mold selection process. These include cost of the process, durability, corrosion resistance, water resistance and lubricity.

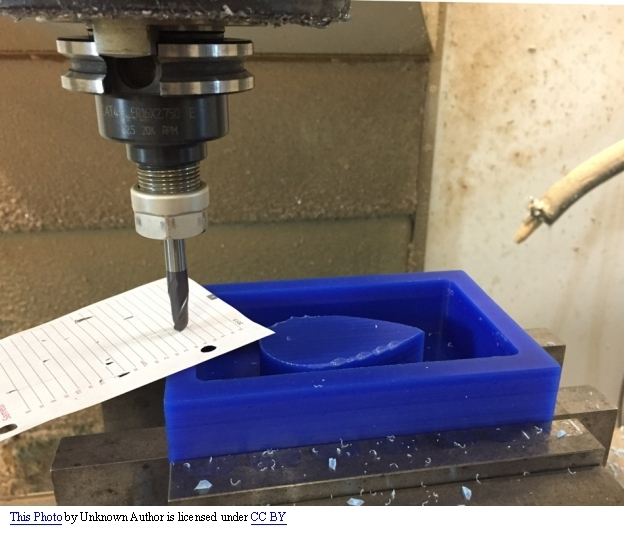

Machining and Fabrication

Machining and fabrication are a very complex and challenging step. It makes sure that the molds have the required precision and dimensions. It involves creation of the individual components of the mold. This also involves creation of the side action mechanisms.

To achieve the appropriate precision level, manufacturers use CNC machines and other specialized equipment.

If you want to achieve optimal performance, make sure to achieve smooth texture and surface finish.

Heat Treatment

Heat treatment is as important and challenging as the machining and fabrication step. The two most important factors to consider are timing and, of course, careful temperature control during the process.

During this process, manufacturers use different types of heat treatments. These include:

Annealing, quenching and tempering.

These heating processes improve the material’s strength, hardness and thermal conductivity. Each of these steps has a different impact on the material; for example, annealing reduces the hardness of the material. This makes the material more suitable for the machining process.

On the other hand, quenching enhances the material hardness. This makes the material more resistant to wear and tear.

Assembly

Assembly is the last step in the manufacturing of side action molds. This involves putting together all the individual components. These components include the angled pins, ejector systems, side action locks etc. If you want to achieve precise movement and operation, then make sure that all components are in sync and in perfect alignment.

Again, you can use specialized tools to ensure optimal performance. Make sure to test and validate before putting it into actual usage. Smooth operations are the result of clearance and tolerance during the assembly stage.

Principle of Designing Side Action Molds

There are some basic principles that guide the working of side action molds. These principles make sure that the molds accommodate the side actions without compromising the injection molding process. Let’s have a look at the basic principles of designing side action molds:

- Make sure that there exists precision alignment and tight tolerances between the main mold components and the side actions. This maintains dimensional accuracy and also reduces wear and tear.

- To reduce part damage, maintain part security, and make sure that the closing and retraction mechanisms are top-notch. The side actions should completely retract and lock during the injection molding process.

- Remember to consider the material choice. Always choose good quality materials that possess the required strength and durability.

- Make sure that you implement efficient cooling channels and heat management systems. This will prevent issues related to thermal expansion.

- The design of side actions should be precise and accurate. They should be easy to maintain, assemble, disassemble and reassemble. This can help in the reduction of production losses.

- Carefully analyze your requirements and design your side action mechanism accordingly.

Integration of Side Actions into Mold Designs

Smooth integration of side actions into mold designs is important. It ensures seamless and uninterrupted working of the mold operations. A perfectly integrated side action is the one that works in alignment with the mold parts, Both the side action components and mold parts offer sufficient space to each other. There should be sufficient space for the side action components to move laterally inside the mold.

But how to achieve smooth and seamless integration of the side action into mold parts?

The answer is through cam and slide mechanisms.

Both cam and slides help in the achievement of smooth movements. Sensors, monitoring mechanisms, litters and pulls are among other options to achieve optimal performance through the integration of side actions into mold designs.

Selecting the Accurate Mold Maker

Many manufacturers need to know which qualities to consider when selecting a mold manufacturer. Here is a list of the qualities you need to consider when deciding a mold manufacturer.

- The mold manufacturer should have ample experience in the mold making industry.

- It should be equipped with the latest technology and processes and should have the right expertise.

- A reliable mold maker is the one that offers a variety of customization options.

- Its pricing system is clear and transparent.

- The after-sales support is up to the mark.

- Communication channels are clear and robust.

- The manufacturer has a good history of manufacturing and supplying high quality molds.

- Remember to have a background check and take testimonials from previous clients.

Benefits of Using Side Actions in Mold Designs

Side actions are a technical aspect of the injection molding process. They offer a variety of advantages that make their usage crucial in the injection molding process. Let’s have a look at their advantages:

Creation of Complex Geometries

Side actions in mold designs make the creation of complex undercut geometries possible. These intricate internal designs are not possible with the traditional two-plate mold.

Versatile Design

The Use of side actions can help designers incorporate complex undercut geometries. This helps in enhancing the functionality of parts. The overall design of the part is enhanced and improved, thus making it more usable and functional.

No use of Secondary Operations

By secondary operations, we mean drilling and additional machining. The Use of side actions usually incorporates such functions that eliminate the Use of drilling and further machining. This reduces the costs associated with post-processing.

Cost Effective

Side action incorporation reduces the operational and manufacturing cost of the injection molding process. This is because they incorporate various operational features inside one molding cycle.

Conclusion

Side actions may seem simple in structure, but they perform many complex functions in the injection molding process. Through their functionality, they help achieve optimal performance by creating complex undercut geometries. They make the whole injection molding process more operational, efficient and cost-effective.

However, it is important to ensure that the side injection mold is of good quality and that the process takes place under expert supervision. Precision and accuracy of the process, especially in the case of angled pins, are also crucial to the success of the whole process.