End-to-End Custom Perfume Bottle Packaging

Custom perfume bottle packaging—mould, glass, alloy & plastic made in-house for cost efficiency

End-to-End Custom Perfume Bottle Packaging

Custom perfume bottle packaging—mould, glass, alloy & plastic made in-house for cost efficiency

End-to-End Custom Perfume Bottle Packaging

Custom perfume bottle packaging—mould, glass, alloy & plastic made in-house for cost efficiency

Factory Area

3000

㎡

Design Awards

Day

eliminates outsource links

+

Cost Reduction

%

Factory Area

3000

㎡

Design Awards

Day

eliminates outsource links

+

Cost Reduction

%

Trusted by 40 + premium brands across the Middle East and Europe, Gozone operates a 3300 ㎡ plantand delivers samples in 7 days. With in-house mould, alloy and plastic production that eliminates 5 + outsource links and cuts total cost by up to 20 %, we are your one-stop perfume bottle manufacturer for cost-efficient custom perfume bottle packaging.

What Can we do

Our Key Benefits

- Fully In-house Production

10 automated lines deliver 10 million+ units per year.

- Top-tier Creative Design

A 10-member design team tracks perfume trends; 3-D renders flow straight into our factory for instant realisation.

- Stringent Quality Control

Our in-house lab runs leak, ethanol-resistance and salt-spray tests to secure premium perfume bottle packaging quality.

- ↓20 % Up to 20 % Cost Saving

Factory-direct glass plus alloy & plastic caps eliminate colour variance and scrap, while integrated design-to-manufacture shortens project cycles by 25 %, driving total procurement savings of over 20 %.

- 7-Day Rapid Sampling

Mould shop and glass furnace work side-by-side, cutting iteration time by 30 %.

- Trusted by 100 + Premium Brands

Gozone is trusted by 40 + premium perfume brands in more than 10 countries, achieving a 65 % repeat-order rate and partnerships that average over four years.

What Can we do

Our Key Benefits

- Fully In-house Production

10 automated lines deliver 10 million+ units per year.

- Top-tier Creative Design

A 10-member design team tracks perfume trends; 3-D renders flow straight into our factory for instant realisation.

- Stringent Quality Control

Our in-house lab runs leak, ethanol-resistance and salt-spray tests to secure premium perfume bottle packaging quality.

- ↓20 % Up to 20 % Cost Saving

Factory-direct glass plus alloy & plastic caps eliminate colour variance and scrap, while integrated design-to-manufacture shortens project cycles by 25 %, driving total procurement savings of over 20 %.

- 7-Day Rapid Sampling

Mould shop and glass furnace work side-by-side, cutting iteration time by 30 %.

- Trusted by 100 + Premium Brands

Gozone is trusted by 40 + premium perfume brands in more than 10 countries, achieving a 65 % repeat-order rate and partnerships that average over four years.

Factory at a Glance.

Our Factory

Step inside Gozone’s 3,300 m² in-house factory and experience the integrated process from alloy and plastic component production to perfume bottle manufacturing. With our in-house production lines, we ensure high efficiency and precision, meeting the demands of premium perfume brands for custom perfume bottle packaging.

Factory at a Glance.

Our Factory

Step inside Gozone’s 3,300 m² in-house factory and experience the integrated process from alloy and plastic component production to perfume bottle manufacturing. With our in-house production lines, we ensure high efficiency and precision, meeting the demands of premium perfume brands for custom perfume bottle packaging.

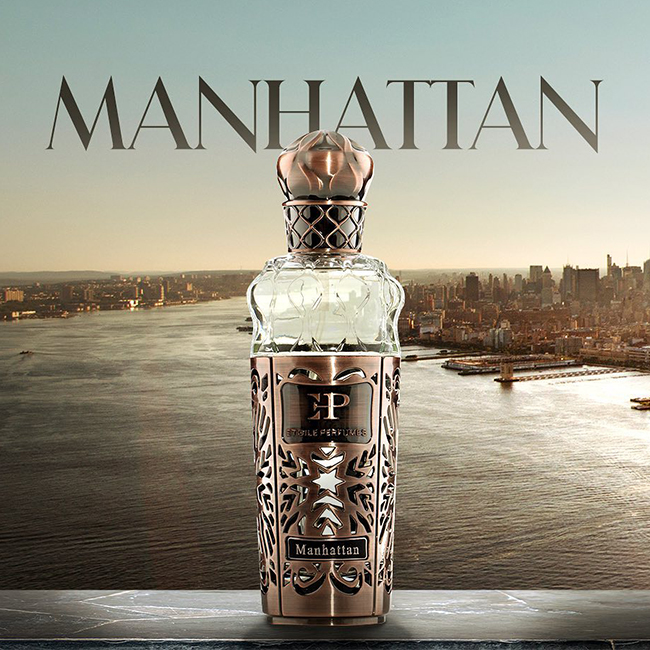

they trust us.

Our Clients

Book a Design Consultation

Your ideas, our expertise! Click here to contact us, and we’ll provide the perfect solution!

Book a Design Consultation

Your ideas, our expertise! Click here to contact us, and we’ll provide the perfect solution!