Introduction to Engraving

Engraving is an ancient practice that has evolved significantly over the centuries.The perfume bottle manufacturing industry uses various types of engraving techniques to beautify its bottles. Engraving adds to the bottle’s aesthetic value and is also a durable way of labeling.

This blog explains the different types of engraving and its important applications in the perfume bottle manufacturing industry. Engraving is an important technique for customizing perfume bottles. In this blog, we analyze engraving and its use in glass perfume bottles from various aspects.

WHAT IS ENGRAVING?

Engraving is an essential component of printmaking technology. The print can be anything from a carving or grooves in glass, wood, plastic, steel, and even metals such as gold and silver. Engraving involves precisely cutting grooves into a flat surface with the help of a burin, and it is known as engraving.

The illustrations on a piece of paper are also part of the engravings.

Depending on the process used and the surface engraved, there are several types of engraving. This is why engraving is an industrial process used on a large scale in manufacturing industries.

A Brief History of Engraving

Engraving is not a modern technology. It has been transformed in accordance with technological innovations. However, the history of engraving can be traced back to almost 540,000 years ago in Indonesia. The earliest engravings were hand engravings on bones, rocks, and ivory during the Paleolithic era. Engravings on stones have also been part of many historical cultures worldwide.

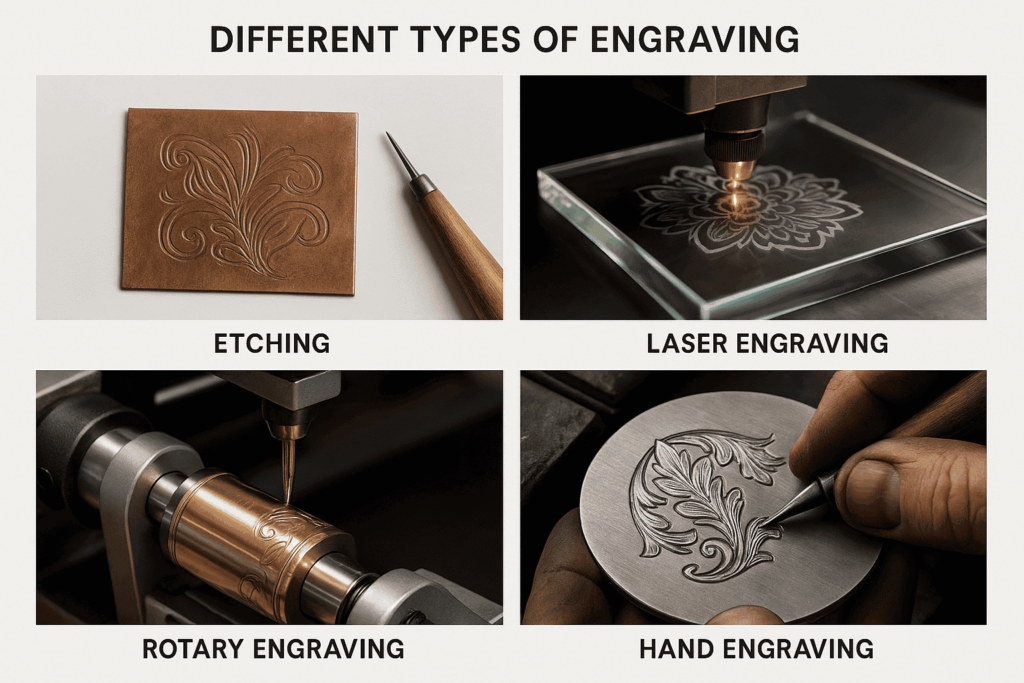

Various Engraving Techniques

This section is the crux of this blog as it revolves around the main topic, i.e., engraving types. Each type of engraving differs in terms of process and technology. This will help us identify and understand the different types and techniques of engraving.

Etching

Etching is a type of industrial engraving. Among other types of engraving, etching uses chemical compounds to create shapes and symbols on the engraving stock. Before the actual process of etching, the engraving stock is first given a chemical bath. The choice of the bathing chemical depends upon the type of material being engraved, which can be plastic, metal, or any other material.

In some cases, certain parts of the engraving stock are covered to keep them safe from the chemical bath. The chemical, in this way, only interacts with the exposed parts. The chemical slowly eats away the exposed parts. After the stencil is removed, the pattern is visible on the engraved material.

Common Material:

Copper, Steel, Aluminum, Nickel, certain types of glass and plastic.

Equipment:

Etching Needles, Roulette wheels, burin engravers etc.

Process Steps:

- Pick a metal plate such as copper, nickel etc.

- Clean and polish the plate to create a uniform flat surface.

- Apply an acid resistant coating on the metal plate surface.

- Create a design on the metal plate surface. You can create the design by pressing into it or scratching. You can use etching tools for scratching and drawing as well.

- Immerse the plate in an acid solution.

- The acid comes in contact with the exposed metal to create the desired etchings.

- Now take out the plate from the acid solution and apply the ink.

- Place a piece of paper on top of the inked plate and pass it through printing press.

- Application of pressure transfers the ink from the metal plate onto the paper.

Laser Engraving

Using a laser to mark or etch the surface of a material is known as laser engraving. Apart from some limitations, laser engraving has several advantages over other types of engraving. Laser engraving is applicable to a wide variety of materials, including stone, glass, plastic, etc.

The type of laser machine used depends upon the magnitude of production. For instance, industrial machining uses large laser machines. Professional engraving, on the other hand, relies on small machines.

A significant advantage of laser engraving is that it ensures precision and accuracy in its designs. What cannot be ignored is the high cost of specialized equipment involved in the process. The laser used in laser engraving is low-powered Carbon dioxide. It creates customized and personalized ornaments, glassware, trophies, etc.

Common Materials:

Glass, Acrylic, Metals

Equipment:

Carbon Dioxide, laser engravers, fiber laser engravers.

Process Steps:

- Prepare the material surface

- Set engraving parameters

- Execute laser engraving

Rotary Engraving

Rotary engraving uses “engraving cutters” to create shapes, symbols and carvings on engraving stock. These engraving cutters are of different shapes and sizes. A CAD or CAM (Computer-aided software or Computer-aided manufacturing) operates or gives instructions for the engraving cutters. This technique is the most versatile Among the different types of engraving. This is because it is compatible with almost all kinds of materials, including metals, plastics, wood, stone, etc.

There are several benefits of rotary engraving. Most important of all is that this technique is very long-lasting. Another creative benefit is that it can create layered effects with contrasting colors or finishes, i.e., it can create colored lacquer on engraved parts as well.

Material:

Wood, plastic, metal.

Equipment:

Rotary Attachment, laser engraving machine.

Process Steps

- Create the design on an engraving software.

- Input the dimensions.

- Prepare the rotary attachment setup by inserting the rotary attachment into the laser machine.

- Mount the object onto the rotary attachment.

- Select the correct power and speed.

- Start the engraving process.

Diamond Drag Engraving

Diamond drag engraving is also known as scratch engraving. This technique has its name because of its purpose. It is because it uses a diamond graver to engrave on engraving stocks. For precise control of the design the diamond tipped engraver is often guided by a computer.

This technique, among other types of engraving, is used to create carvings on trophies. It makes a look that is quite similar to handcrafting.

Diamond engraving has several advantages. It produces deeper cuts, which enhance the look of metal objects. The process is quick, easy, and gives a sharp finish.

Materials:

Plastics, metal, glass and certain types of stones.

Equipment:

Diamond tipped engraver.

Process Steps:

- Prepare the material

- Set up the engraving machine

- Guide the tool along the desired design.

Hand Engraving

Quite different from industrial engraving, hand engraving produces unique pieces of art because it is the work of an artist. An artist uses a small engraving tool to carve unique designs. It is not just time-consuming but also a very labor-intensive process.

The engravers used in this process are burin, chisels, or gravers. It is always better to polish the surface before engraving to get more precise and better-finished results.

The surface grooves of the engraved design is often filled with ink to enhance visibility. This technique is common in engraving luxury items such as titanium and gold jewelry.

Materials:

Metals, Leather.

Equipment:

Burin, Chisels, Gravers.

Process Steps:

- Sketch the design on the object.

- Secure the workpiece into a clamp.

- Carefully cut the design with the graver.

- Clean the debris.

CNC Engraving

As the name suggests, CNC engraving uses CNC machines that operate and control the whole engraving process. It is amongst the most popular types of engraving in industrial manufacturing.

The workings of CNC engraving are quite simple. The Computer operates a spindle and drive system that engraves the material in specific patterns. The user inputs the data into the Computer. Then, the Computer guides the CNC machines to create the desired result for the material.

There is a reason behind the increasing use and popularity of CNC engraving in industrial manufacturing. First, it saves a lot of manual labor. Second, it helps manufacture engraved products in bulk.

Material:

Metal, Wood, Various plastics.

Equipment:

CNC machines, specialized engraving bits.

Process Steps:

- Create the design using a CAD Software.

- Convert the design into a CNC Program.

- Set up the workpiece into the CNC machine.

- Run the program to automatically create the design onto the workpiece.

Engraving Vs Engraving Marking-What’s the Difference?

You will be amazed to know that engraving and engraving marking are different processes. Although they are distinct in their applications, they are sometimes used interchangeably.

Engraving marking is less commonly used in industrial applications than engraving, which alters the color of the engraving material surface.

Types of Engraving Machines

There are several types of engraving machines used in different applications. In this section we shall analyze the various types of engraving machines along with their functions and applications. Let’s have a look at some of them:

Mechanical Engraving Machine

Mechanical engraving machines have been in use for a long time. These machines use a cutter to mark the material with the desired design. A stencil or a model transmits the design onto the engraving material.

Dot Peen Engraver

If you want heavy-duty designs that ensure durability, dot-peen engraving machines should be your best choice. Dot-peen engravers are ideal for creating markings on hard materials such as metals. They use a stylus to create a series of dots on the surface of the engraving material.

Dot-peen engravers are widely used in industrial engraving applications. Unlike other types of engraving machines, they create serial numbers and bar codes for industrial components.

Jewelry Engraver

Engraving jewelry is an intricate and complicated process. You need to engrave delicate designs with precision. Therefore, you need advanced machines for this purpose. Jewelry machines meet all these criteria. These are a subset of the laser machines. They can engrave designs on both flat and curved surfaces.

What is even better about jewelry machines is their size. They are small enough to be placed inside shops, which aids in customer personal customization. Customers can ask to create personalized designs on jewelry just in front of their eyes.

CNC Engraver

A CNC engraver consists of a spindle and a spinning tool. It is known for its precision and flexibility. Because of its productivity and accuracy, it is a great tool for any business. It is also compatible with a variety of materials, such as metals, wood, plastic, etc.

If your business revolves around advertising, building, and making things, you should definitely consider using a CNC engraver. It can create top-quality engraving patterns on a variety of materials.

Application of Engraving in Perfume Bottle Manufacturing

The perfume bottle manufacturing industry involves the application of various types of engraving techniques. Engraving is also used in the design and manufacturing of perfume bottles. There are several reasons for using engraving in perfume bottle manufacturing and packaging.

Not only is engraving an essential part of the production and design process, but it also contributes to branding, customization, and enhancing the overall aesthetics of the perfume bottle.

The use of various types of engraving techniques, such as laser engraving, etching, and mechanical engraving, depends upon several factors. These include the material of the bottle, the complexity of the design, and the production requirements.

Several factors drive the application of engraving in the perfume bottle industry. These include durability, customization, and aesthetic appeal. Each of these factors plays an important role in making sure that the finished product stands out in the competitive market. In this section, we shall analyze the importance of engraving in these three key areas.

Durability and Quality Assurance

Durability is among the most critical factors that enhance the value of a glass perfume bottle. Of course, you would never like your favorite fragrance to be stored and packaged in a damaged or easily breakable bottle. The same is the case with the application of engraving on glass perfume bottles.

Other labeling methods, such as stickers and printed labels, are prone to wearing off with time. They lack durability. Handling, moisture, and different environmental conditions negatively impact them. This is where engraving takes the edge. Engraved details are permanent. Logos, product names, and intricate patterns—whatever you engrave on a glass perfume bottle stays on it throughout the life span of the bottle.

Luxury perfume brands always favor using different types of engraving techniques on their perfume bottles. Engraving ensures longevity and timeless appeal, which is their competitive edge. The permanence of engraved details assures customers that the perfume is of premium quality. It ensures that the product is authentic.

Engraved markings are also perceived as a security feature. They ensure brand protection since the brand’s name is permanently engraved on the bottle. Manufacturers often engrave batch numbers and serial numbers onto glass perfume bottles to trace them and determine their age afterward.

Branding and Aesthetic Enhancement

We have often mentioned in the blog that engraving enhances the aesthetic appeal of the glass perfume bottle.

But How?

Engraving makes glass perfume bottles look luxurious and appealing. You should never ignore the importance of glass perfume bottles in determining the quality of the perfume. A perfume is not just about the fragrance. The glass perfume bottle is also an essential part of the branding process. Consumers have a vast appreciation for beautifully crafted glass perfume bottles.

Engraving helps perfume bottle manufacturers add a sophisticated touch to their products. Different types of engraving result in intricate patterns, elegant typography, and detailed artistic designs.

Using various kinds of engraving, perfume bottle manufacturers can create deep, textured patterns or subtle, elegant engravings that complement the shape and material of the perfume bottle. Manufacturers often use frosted engravings, gold or silver inlays, and 3D effects to enhance the bottle’s exclusivity.

Luxury perfume bottles and limited-edition perfumes use a fusion of engraving with other decorative techniques. These techniques include ornate embellishments, floral patterns, and even gemstone inlays. These decorative techniques create a luxurious look. The application of such details enhances the brand identity, making the glass perfume bottle an extension of the fragrance itself.

Personalization and Market Appeal

You can never deny the critical role of engraving in the customization of glass perfume bottles. Perfume brands use different types of engraving techniques to offer customized perfume bottles to their customers.

Personalized engraving is a popular trend in the fragrance industry. It allows consumers to add a unique touch to their purchases. Several brands enable customers to get their names, initials, or special messages engraved on glass perfume bottles. This makes the perfume bottles an ideal gift for special occasions.

Customization through engraving is also used for exclusive product lines, special releases, and brand collaborations. By offering limited-edition engraved bottles, brands create a sense of exclusivity and uniqueness, which enhances their market appeal. Personalized engraving makes each bottle one-of-a-kind. It strengthens the emotional connection between the consumer and the brand.

CONCLUSION

Perfume bottle manufacturers use different types of engraving to add a customized and decorative touch to glass perfume bottles. Engraving enhances the visual appeal of the bottle and the brand identity.

What started as an ancient technique is now a widespread phenomenon in the perfume bottle manufacturing industry. It not only ensures the durability of the perfume bottle but also increases its market value. Engraving is undoubtedly a timeless and valuable technique that improves the exclusivity of the perfume packaging.

Glossary

| Sr No | Term | Meaning |

| 1 | CNC | Computer Numerical Control |

| 2 | Dot Peen | A mechanical engraving process that creates permanent and durable markings. |

| 3 | CAD | Computer Aided Design |

| 4 | CAM | Computer Aided Manufacturing |

| 5 | Etching | An engravibng process whereby metals are immersed into acids to be capable of holding inks. |