Glass craftsmanship marries beauty with strength. Impact and durability testing are the guardians of this union. Whether it’s perfume bottles or crystal vials, these tests guarantee our creations possess elegance and resilience in equal measure.

Building upon the foundation of basic testing, our standardized tests and meticulous evaluations guarantee that these glass marvels remain intact, resilient, and enduring. Explore the science behind these tests in our series, as we lay the foundation for lasting glass creations.

Impact Testing: Enhancing Glass Bottle Durability

Role and Purpose

Impact testing plays a pivotal role in the world of glass bottle manufacturing, particularly for items like delicate perfume bottles.

This critical procedure acts as a sentinel, evaluating the bottle’s ability to withstand external forces and impacts. Its primary role is to ensure that the bottles maintain their structural integrity even when subjected to sudden shocks and stresses.

The core purpose of impact testing is to verify the glass bottle’s resistance to impact, ensuring that it can withstand external forces without deformation or breakage.

By simulating real-world scenarios where bottles might accidentally collide or drop, this test ensures the bottle’s resilience and safety.

It empowers us to design bottles that not only exude elegance, but also excel in impact resistance, providing protection for valuable contents like perfumes.

Testing Instruments and Methods

To perform impact testing, we employ specialized instruments and methods tailored to simulate various impact scenarios. These methods include drop testing and pendulum impact testing, allowing us to evaluate the bottle’s response to sudden impacts accurately.

In summary, impact testing is our commitment to delivering glass bottles that not only showcase beauty but also demonstrate exceptional strength, adhering to the highest Impact Testing Standards and Bottle Safety Testing.

Pressure Resistance Test: Strengthening Glass Bottle Integrity

Role and Purpose

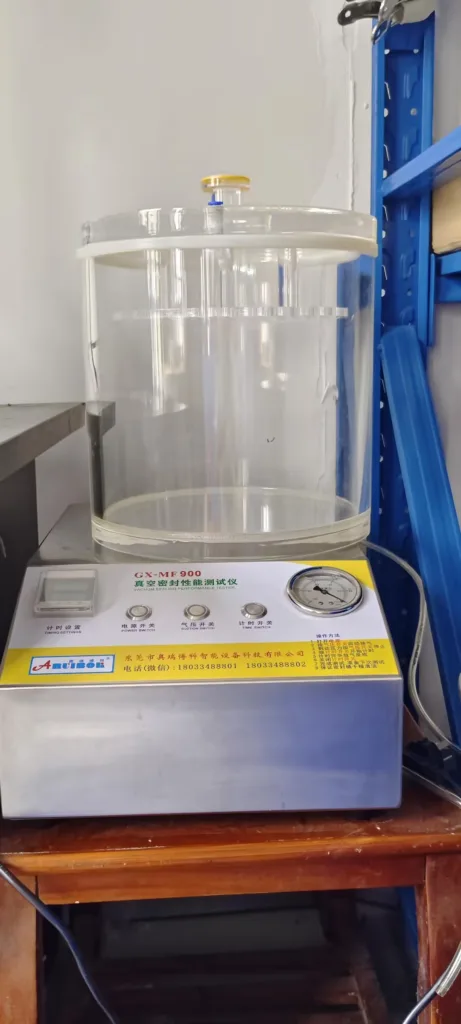

Pressure resistance testing is a critical checkpoint in the manufacturing of glass bottles, including delicate perfume bottles. It acts as the guardian of bottle strength, evaluating how bottles endure internal and external pressures. Its primary role is to ensure bottles maintain their structural integrity when subjected to varying levels of pressure.

The core purpose of pressure resistance testing is to validate the glass bottle’s capacity to withstand pressure without deformation or breakage. By simulating scenarios where bottles may face increased internal pressure, this test ensures their resilience and safety.

It empowers us to design bottles that not only exude elegance but also excel in pressure resistance, a crucial attribute for containers that hold carbonated beverages, where maintaining the bottle’s integrity is paramount.

Testing Instruments and Principles

To conduct pressure resistance testing, we utilize specialized equipment such as pressure test chambers. These instruments operate on the principle of subjecting bottles to controlled internal pressure, mirroring real-world conditions. By incrementally increasing the pressure, we monitor the bottle’s response to ensure its reliability and safety.

In summary, pressure resistance testing is our pledge to deliver glass bottles that epitomize both beauty and unmatched strength, adhering to the highest Impact Testing Standards and Bottle Safety Testing.

In summary, pressure resistance testing is our pledge to deliver glass bottles that epitomize both beauty and unmatched strength, adhering to the highest Impact Testing Standards and Bottle Safety Testing.

Thermal Shock Resistance: Safeguarding Glass Bottle Durability

Role and Purpose

In the intricate world of glass bottle manufacturing, thermal shock resistance testing stands as a sentinel, ensuring the strength of bottles, including delicate perfume containers. Its pivotal role is to assess how bottles withstand abrupt temperature fluctuations without yielding to stress or fractures.

The core purpose of thermal shock resistance testing is to validate the glass bottle’s capability to endure sudden temperature changes without deformation or breakage.

By subjecting bottles to rapid shifts between extreme hot and cold conditions, this test certifies the bottle’s resilience and safety. It empowers us to design bottles that not only radiate elegance but also excel in thermal shock resistance, preserving the integrity of valuable contents like perfumes.

Testing Instruments and Techniques

To execute thermal shock resistance testing, we deploy specialized equipment and techniques, meticulously replicating extreme temperature variations. Our methods involve exposing the bottles to swift transitions between scorching heat and freezing cold, mimicking real-world scenarios.

In essence, thermal shock resistance testing underscores our unwavering commitment to deliver glass bottles that embody both sophistication and peerless durability.

It adheres to the highest Impact Testing Standards and Bottle Safety Testing, ensuring that your treasured contents, such as perfumes, remain unscathed by temperature challenges.

Looking Forward: Unveiling More Tests

As we draw this chapter of glass bottle testing to a close, we’ve explored foundational tests that ensure durability and safety. Next, we dive deeper into specialized procedures, revealing how we craft glass bottles that blend elegance with resilience.

Stay tuned for an in-depth look at these tests, as we continue our commitment to creating exceptional bottles that stand as both functional and artistic marvels.