From perfume bottles and candle holders to food jars and drink containers, glass packaging touches every part of our lives. But have you ever stopped to think about why these glass containers look and feel the way they do?

It all comes down to surface treatment, a process as interesting as it is important. In this article, we’ll peel back the layers and explore the fascinating world of glass container surface treatments.

Spraying

Behind every gleaming, sturdy glass container, there’s a tale of spray treatments. Hot end and cold end coatings, applied at precise moments in production, bestow a smooth gloss and enduring strength. These treatments are a testament to the marvel of glass production, delivering practicality and elegance in equal measure.

Translucent Color Spraying

Translucent color spraying brings a tint of intrigue to glass containers. In this process, a specialized spray gun applies a fine mist of color onto the glass surface. But it’s not an opaque coat.

The spray is designed to mingle with the glass’s natural transparency, creating a delicate interplay of color and clarity. And it’s not just about aesthetics – the color layer also doubles as an extra shield, enhancing the container’s durability.

Multicolor Coating

In the world of glass container production, gradient spraying is a technique that beautifully marries precision and aesthetics. It involves carefully adjusting the density of sprayed color, creating a harmonious transition from one hue to another across the container’s surface.

This process not only results in a captivating visual effect but also introduces an element of individuality to each piece. A gradient-sprayed glass container stands out, not just for its functionality, but for its distinct character and appeal.

Internal Coating

In the realm of glass container production, interior spraying plays a key role in adding aesthetic charm. The process imbues an inner radiance to the container by applying a coating to its inside surface.

However, while beautiful, it’s not always suited for every content – certain products might interact with the coating material. Interior spraying is indeed a double-edged sword, striking a balance between visual attraction and conscientious use.

Spot coating

Spot coating brings an extra layer of sensory experience to glass container usage. This technique, focused on selective application of coating, creates interesting texture contrasts on the surface of containers.

Whether it’s to highlight important text or add a playful design element, spot coating introduces a touchable dimension that invites exploration. It’s a design detail that adds curiosity, beauty, and a unique feel to our glass containers.

Crackle coating

In the realm of glass container design, crackle coating is a delightful anomaly. This technique employs a special coating that intentionally shrinks and cracks when dried, resulting in a fine network of lines that mimic the beauty of aged artifacts.

It adds a fascinating tactile element and a captivating aesthetic appeal to the containers, perfect for those seeking a blend of tradition and trend in their packaging.

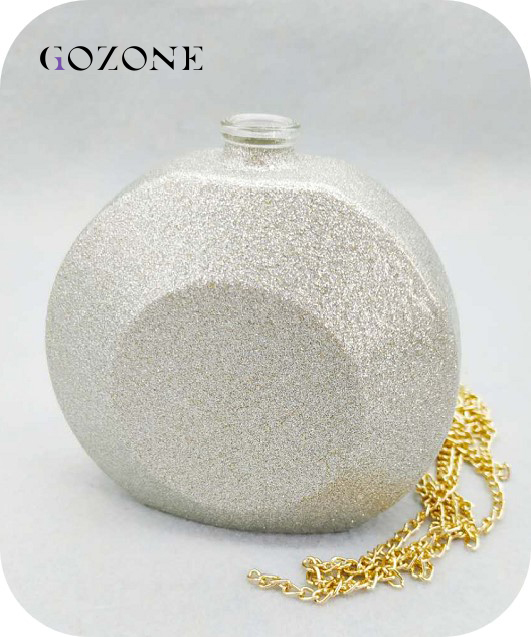

Glitter coating

Glitter coating adds that extra sparkle to glass containers that makes them truly eye-catching. By incorporating tiny reflective particles into the coating, we create a surface that sparkles and glows, capturing light in an ever-changing play of colors.

This treatment adds a glamorous touch, making these containers ideal for high-end cosmetics, festive beverages, or any product that aims to dazzle and delight its audience.

Soft touching coating

Step into the sensory realm of glass container production with soft-touch coating. This process involves applying a special coating that gives the glass container a unique, velvety texture. More than just a tactile delight, it also provides enhanced grip, making the containers safer to handle. It’s the perfect blend of touch and sight – a visual treat that invites you to reach out and feel the quality.

Conclude

When it comes to glass container packaging, the magic lies in the coating treatments. From gradient and translucent color coatings to the tactile allure of soft touching, spot, and crackle coatings, or the glitter coating’s sparkle, each process adds its unique charm.

They enhance not only the visual appeal but also the user experience, transforming every container into a mini masterpiece.