The increase in demand for unique and customized packaging and printing has led to the invention of various printing techniques.

The hot stamping technique is one of the innovative printing techniques of the twenty-first century. Although the technique has its roots in the nineteenth century, the modern has undoubtedly transformed its execution.

This blog includes detailed information about the hot stamping process, its applications, advantages, and limitations. Let’s read further to know more about the hot stamping printing technique.

What is Hot Stamping

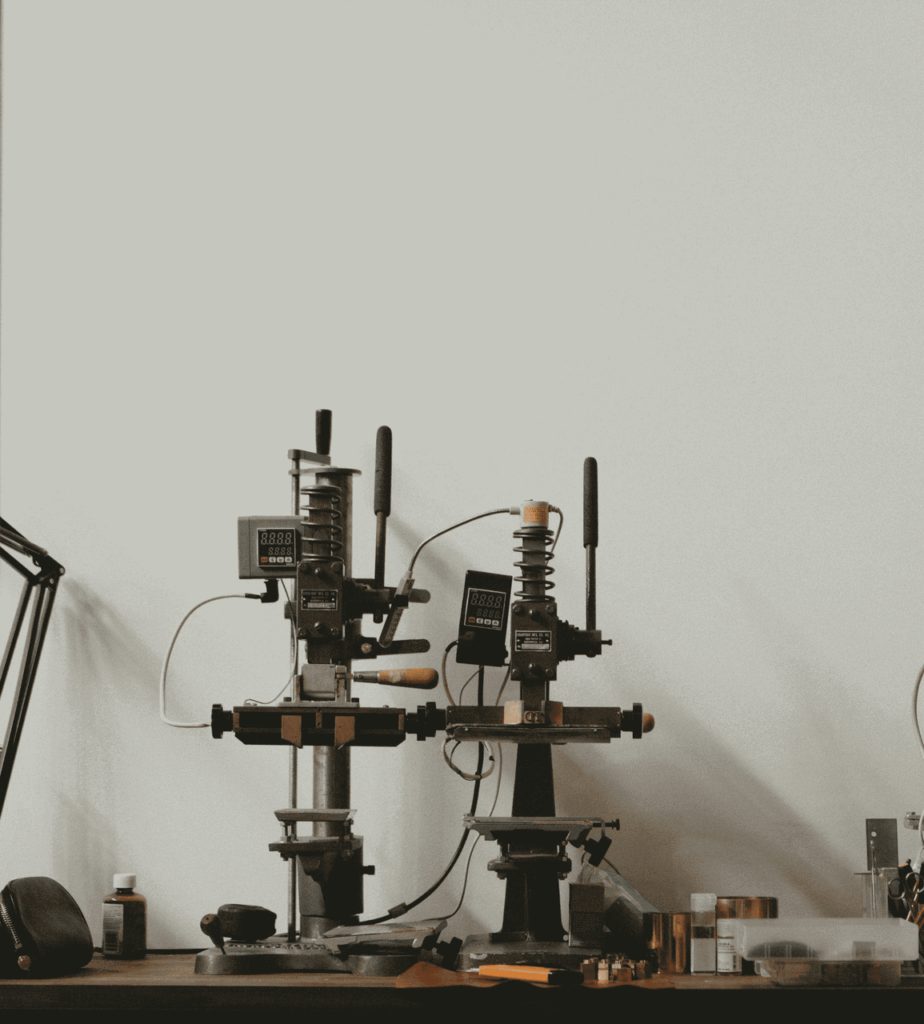

Hot stamping is a lithography printing process. The process involves heated image molds or stamping dies. These images or dies transfer the metal foils or pre-dried inks onto a particular surface.

The hot stamping process involves the use of a hot stamping machine. The hot stamping machine heats the engraved mold or dye. This heated mold or dye then presses the marking foil on the surface of the object.

Only that portion of the foil is stamped on the object in contact with the hot stamp. Engineers, in this way, are able to create beautiful and creative embossed patterns on different objects.

There are two classifications of the hot stamping process, i.e

●Direct Hot stamping

●Indirect hot stamping

Let’s know more about them.

Direct Hot Stamping

The direct hot stamping process consists of the following steps:

- First of all, a furnace heats a blank

- The blank is then transferred to the pressing

- It is then formed and quenched in the hot dies.

- Blank is cooled down.

The formation of the product is followed by the quenching of the blank in hot dies and cooling it down. In a follow-up process, the product is trimmed by laser for further finishing.

Direct hot stamping is more suitable for parts with simple geometry.

Indirect Hot Stamping

The indirect hot stamping process consists of the following steps:

- The blank is first prestamped at room temperature

- Later, it is heated for austenitization

- Lastly, it is subjected to calibration and quenching into the die.

Indirect hot stamping is more recommended for complex geometrical patterns.

Different types of Foils used in the Hot Stamping Process

For the creation of unique and distinctive packaging, various types of foil materials are used in hot stamping. Let’s have a look at some of them.

| Metallic foils: | Metallic foils include metals such as copper, gold, silver, etc. They create an attractive patina because of the different types of metals in them. |

| Matte Pigment Foil: | This foil has an intense depth of color. However, it looks muted in appearance. |

| Gloss Pigment Foil: | As the name implies, this foil creates a glossy texture. It offers a non-metallic finish across a variety of colors. |

| Holographic Foil: | To create a unique and innovative look, holographic foil transfers holographic images to the object’s surface. |

| Special Effects Foil: | As the name indicates, special effects foils create the effect and texture of special materials. These materials include leather, pear or even marble. |

Common Materials Used for Hot Stamping

The common metals used in the hot stamping process are copper, magnesium, brass, and steel. Many brands that add a premium touch to their packaging use silver. That is why the process is sometimes referred to as silver stamping.

Dies that use magnesium are the least expensive and easily available. However, magnesium dies are not durable at all.

Among durable dye options are copper and brass. However, they are expensive and, therefore, increase the cost of production.

Other premium dye options include gold and silver.

Advantages of the Hot Stamping Process

Clean and Organized Process

The hot stamping process, unlike other printing processes, does not involve any mixing of liquids. It is a simple, organized, and clean process involving metal foil and a hot stamping machine. Therefore, it is neater.

High-Quality Results

The hot stamping process produces high-quality printing results. No matter what the pigment or material of the metal foil is, it always adheres well with the substrate. Certain materials, such as leather, require sp[specialized foils for printing through the hot stamping process. This point has to be taken care of by the engineers.

Durable

Although metallic files in this process are quite durable, environmental conditions can cause them to fade. However, since the dye is metallic, the dye on the object’s surface remains intact even if the metallic foil fades away.

Energy Savvy

The hot stamping process requires energy in the form of heat. This heat can be supplied from various sources, such as induction heating. Using such cost-effective and energy-efficient heating methods makes the process more energy-savvy.

Limitations of the Hot Stamping Process

Blurred images

The images obtained through the hot stamping process are either blurred or dizzy in appearance. If the temperature of the stamping plate is high, it might exceed the maximum temperature limit of the metal foil. This will cause expansion of the metal foil, and the resulting print will become blurry.

Uneven Text edges

When the pressure of the printing plate is nonuniform, it causes uneven text edges. The reason is that nonuniform pressure causes uneven adhesion of the print to the object’s surface.

Missing strokes on the image

Sometimes, the image print on the object might have missing strokes. It is because the stamping plate is damaged. The solution to this problem is very simple. All you need to do is change or replace the stamping plate.

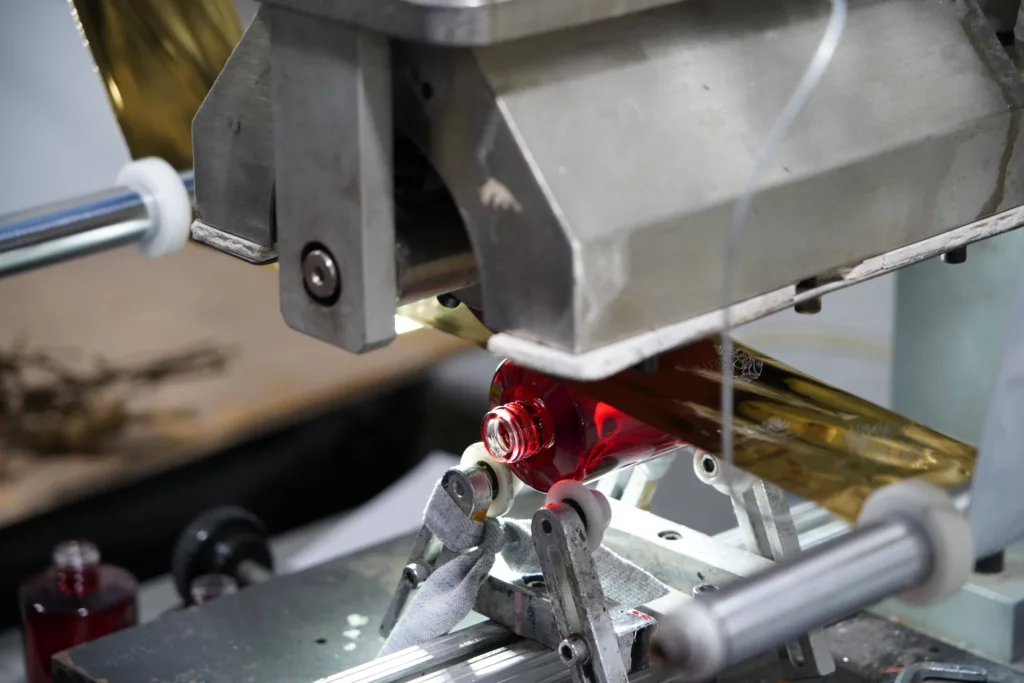

Hot Stamping on Glass Perfume Bottles

The best feature of the hot stamping technique is that it applies to glass, plastic, wood, and even metal. Even if the object’s surface is coated, you can still print using hot stamping. Of course, you need to use the metal foil.

This makes the hot stamping technique a very useful printing packaging method in the perfume manufacturing industry.

The hot stamping technique can be applied to create multi-color glass perfume bottles. No matter the shape of the perfume bottle, it can be printed using the hot stamping technique. Square, oval, and triangle shapes of glass perfume bottles are eligible for printing under this technique.

Conclusion

Hot stamping is a decorative foil printing technique that operates under high temperatures. Different types of metal foils and dyes create different printing textures and colors.

This technique is cost-effective and can create various packaging options for different materials. It is widely used in glass manufacturing to create custom printing on glass perfume bottles.